会员资格

登入

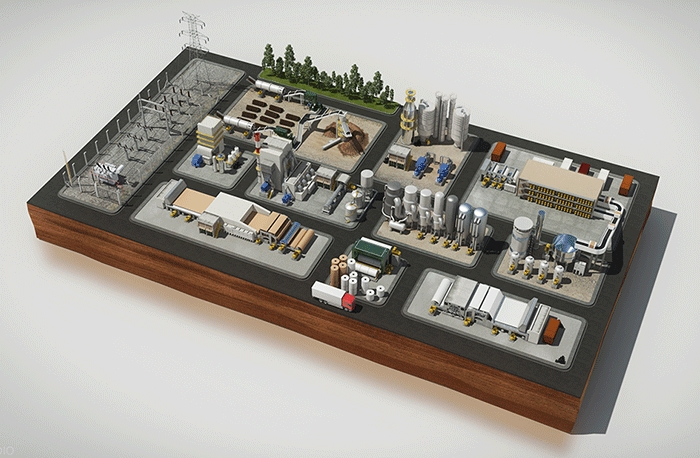

High perfomance and continous productivity for Pulp & Paper

WEG will be a part of your project delivering high performance products offering energy efficient solutions for your application from the beginning to the end of the production process. With our service network, we aim to ensure your plant will never stop.

The Chip Yard is where the pulp manufacturing process begins. WEG provides a full drive and automation solution for the equipment to receive, handle, classify and store chips, which will be used in the pulp process or for heat and power supply generation.

It is important that the wood chipper is reliable and the quality of output consistent. WEG supplies motors with the high torques required by the application through to the most advanced automation systems, including robust electrical infrastructure.

WEG supplies a complete solution to drive the shredder, one of the most important processes in the production of Pulp & Paper. The drive must be prepared for high inertias and high resistant torques to operate the shredder effectively.

A pony-motor can reduce the impact of drawing power direct from the grid to start the shredder which requires a starting current much higher than the rated current.

Our solution for the power supply of the refiner provides efficiency with the best cost effectiveness. Our CFW11 drive can be configured with two outputs using the same frequency drive for the Pony-Motor and the motor of the screw feeder. In this application, the motor and drive set is able to operate with constant torque throughout the speed range, in addition to withstanding momentary over speed when required.

In this step, the objective is to reduce the moisture content of the pulp. Going into the drying line, the pulp passes through the formation and pressing systems, arriving at the drying tunnel with a dry level of approximately 55%. In this tunnel, the heat exchange with the air occurs, finishing the drying process with a dry level of approximately 90%. WEG motor line W22 WELL (WEG Extra Long Life) was specially designed to maximize the reliability and productivity of equipment where continuous processing occurs.

WEG offers complete solutions for the energy generation system with products developed to the highest quality and technology standard required worldwide. It also has a team of engineers and specialists in generation and electric systems available to help you with the most efficient technical solution.

Implementing automation in the paper manufacturing process increases reliability and performance, and it improves the quality of the final product. WEG has innovative solutions for the paper segment, providing the full electrical package, including motors, drive panels with frequency drives, control and supervisory systems, engineering services and commissioning of the pulp mass preparation process, paper machine and rewinders.

A consistent energy supply is a must for any operation. Offering more and more complete solutions, WEG supplies a wide range of transformers and conventional substations, ensuring total reliability in energy supply for a wide variety of applications.

WEG Coatings offers technology in coatings for different kinds of aggressive environments. They are products with greater color and gloss retention, resistant to contacts with chemicals and high temperatures. Whether preventing accidents with corrosion, reducing expenses with maintenance in the painting or avoiding non-scheduled shutdown in production, WEG high performance coatings provide greater productivity and profit for your company.

The different characteristics found in the pulp & paper industry, such as the contact with aggressive compounds (acids, bases) and solid contaminants, besides the presence of high humidity, high temperatures, sulfides and other corrosive materials, generate the demand for high-performance materials and coatings.

To save energy is the best power policy. It is estimated that, annually, 10% of all the energy generated in Brazil is wasted (ABESCO); the Brazilian industrial sector consumes around 40% of the electric power of the country, and 2/3 of this energy is used in driving systems. The reduction of energy consumption by means of more efficient use provides the industry with greater competitiveness and productivity, in addition to greater energy availability and reduction of environmental impacts.

WEG offers maintenance checks, rework and rerating services of medium and large electrical machines, of its own manufacture or other manufacturers, with flexibility to be performed at the factory or in the field.